What is HSE (Health, Safety, and Environment) Management in Organizations

Prepared and edited by: Dr. Amin Padash, President of the Iranian Scientific Association of Health, Safety and Environment Management and Engineering (HSEME)

Health, Safety, and Environment (HSE) management refers to the systematic approach organizations adopt to ensure the health and safety of their employees while minimizing their environmental impact. It encompasses policies, procedures, and practices that are designed to manage risks related to health, safety, and the environment effectively. HSE management is not only about compliance with laws and regulations; it is also about fostering a culture of safety, improving operational efficiency, and enhancing organizational reputation.

What are the Best Practices for HSE Management System?

Prepared and edited by: Dr. Amin Padash, President of the Iranian Scientific Association of Health, Safety and Environment Management and Engineering (HSEME)

Implementing best practices for Health, Safety, and Environment (HSE) is crucial for creating a safe workplace and promoting a safety culture. These practices help minimize risks and enhance organizational performance, employee morale, and public perception. Below are some of the best HSE practices, illustrated with examples and extended descriptions to demonstrate their importance and effectiveness.

- Comprehensive Risk Assessment

Best Practice: Conducting regular and thorough risk assessments is fundamental in identifying potential hazards and evaluating the associated risks in the workplace.

Example: A company might conduct a risk assessment in the construction industry before starting a new project. This involves identifying hazards such as working at heights, heavy machinery, or potential exposure to harmful materials. The assessment would include evaluating the likelihood of these risks and their potential impact on workers.

A detailed risk assessment process often includes site inspections, employee feedback, and historical data analysis. This information helps in formulating specific control measures, such as using safety harnesses for workers at heights, establishing barriers around machinery, or implementing stringent safety protocols when handling hazardous substances. Regular assessment updates are also essential as projects evolve or new hazards emerge.

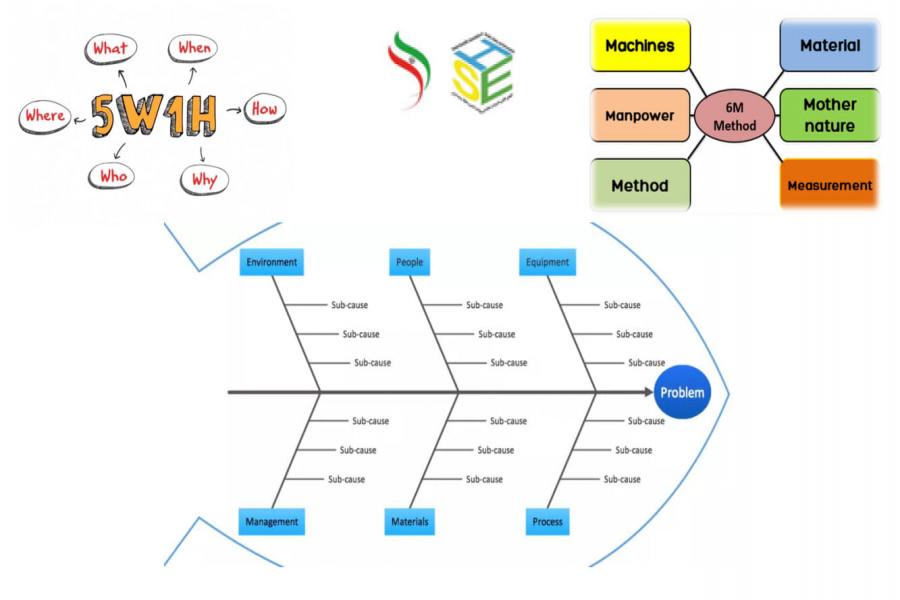

Problem-solving with the fishbone technique and the 6M and 5W methods

- Fishbone Diagram Overview

The Fishbone Diagram is a tool used to identify and analyze the root causes of a specific problem. It helps visualize how various factors contribute to the outcome. The diagram is structured like a fish, with a central spine representing the problem, and the "bones" representing multiple categories of causes.

In the context of problem-solving:

- Categories (bones) help break down complex issues.

- Root causes are identified by systematically analyzing different factors.

- 6M Method: Categories of Causes

The 6M is widespread in manufacturing and industrial environments but can also be adapted to other fields. These six categories help analyze the potential causes of a problem.