Prepared and arranged by: Dr. Amin Padash, HSEQ Coach, President of the Iranian Scientific Association of Health, Safety and Environmental Management and Engineering (HSEME)

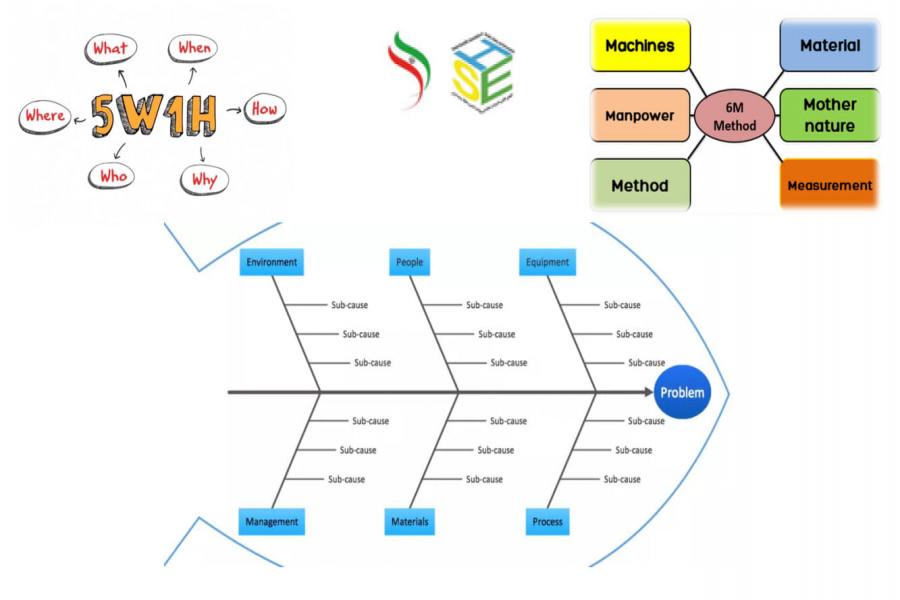

- Fishbone Diagram Overview

The Fishbone Diagram is a tool used to identify and analyze the root causes of a specific problem. It helps visualize how various factors contribute to the outcome. The diagram is structured like a fish, with a central spine representing the problem, and the "bones" representing multiple categories of causes.

In the context of problem-solving:

- Categories (bones) help break down complex issues.

- Root causes are identified by systematically analyzing different factors.

- 6M Method: Categories of Causes

The 6M is widespread in manufacturing and industrial environments but can also be adapted to other fields. These six categories help analyze the potential causes of a problem.

6M Categories and Their Application:

- Man (People):

- Human-related issues such as lack of training, inadequate skill levels, negligence, or fatigue.

- In HSEQ, this could be improper safety training or human error.

- In ESG, human factors could involve lack of awareness or non-compliance with sustainability practices.

- Machine:

- Equipment-related issues, like equipment failure, improper functioning, or outdated machinery.

- In HSEQ, this could involve faulty machinery causing safety hazards.

- In ESG, this might be machines that are energy-inefficient and contribute to carbon emissions.

- Material:

- Issues with raw materials, such as quality, availability, or contamination.

- In HSEQ, this could be low-quality materials leading to hazardous products or situations.

- In ESG, it could refer to unsustainable or high-emission materials being used.

- Method:

- Procedural or process issues, like inefficient work methods or outdated workflows.

- In HSEQ, it may involve improper work processes leading to safety hazards.

- In ESG, inefficient processes that lead to resource waste or environmental harm.

- Measurement:

- Problems with data collection, reporting, or measurement tools.

- In HSEQ, inaccurate or insufficient safety audits, or lack of proper monitoring tools for safety.

- In ESG, inaccurate tracking of emissions, waste, or sustainability efforts.

- Mother Nature (Environment):

- External environmental factors that affect the situation.

- In HSEQ, this could involve environmental conditions like poor weather causing accidents.

- In ESG, external environmental factors, such as climate change, influencing sustainability targets.

- 5W Method: A Broader Approach for Analyzing Causes

The 5W method uses questions to analyze the problem, focusing on understanding the "what", "why", "where", "when", and "who".

5W Categories and Their Application:

- What:

- What is the problem? Identifying the exact issue or effect you are trying to address.

- In HSEQ, the problem might be something like “increased workplace injuries”.

- In ESG, the problem might be “rising carbon emissions” or “unsustainable resource usage”.

- Why:

- Why did the problem occur? Analyzing the root causes of the issue.

- In HSEQ, why there are injuries (e.g., lack of safety protocols, human errors, equipment failure).

- In ESG, why there are high emissions (e.g., inefficient energy sources, outdated machinery, wasteful processes).

- Where:

- Where did the problem occur? Locating the specific area or region of impact.

- In HSEQ, this might be a specific department, site, or equipment.

- In ESG, this could be a particular facility or business operation contributing heavily to carbon emissions.

- When:

- When did the problem arise? Understanding if the issue is recurring or new.

- In HSEQ, it could be related to specific shifts, periods of the year, or following certain changes.

- In ESG, the rise in emissions might coincide with an increase in production or expansion into new markets.

- Who:

- Who is involved? Identifying the people, departments, or stakeholders involved in the issue.

- In HSEQ, this could involve workers who are directly involved in accidents, safety officers, or managers.

- In ESG, it could involve the corporate sustainability team, local regulators, or supply chain partners.

- Step-by-Step Solution Process with Examples

Now let’s apply the Fishbone Diagram using 6M and 5W methods to analyze specific issues in HSEQ and ESG.

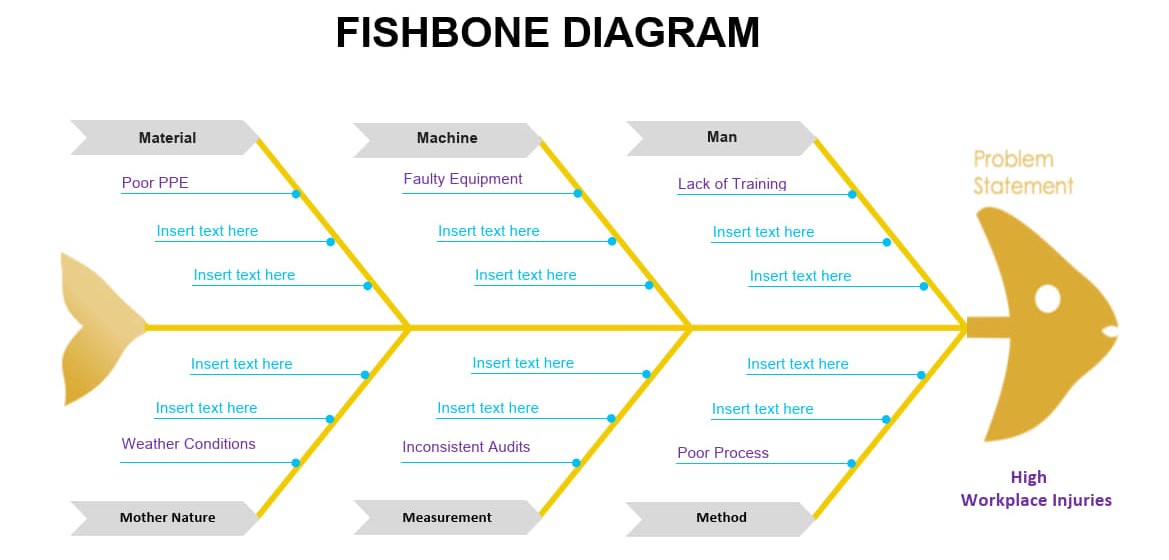

Example 1: HSEQ - High Number of Workplace Injuries

Problem: High number of workplace injuries.

Step 1: Define the Problem

- Problem: High number of injuries at the manufacturing site.

Step 2: Categorize Potential Causes Using 6M

- Man (People):

- Lack of safety training.

- Employees not following safety protocols.

- Fatigue from long working hours.

- Lack of personal responsibility or negligence.

- Machine (Equipment):

- Faulty equipment.

- Lack of regular maintenance.

- Use of outdated machinery.

- Poor ergonomics in tools and machines.

- Material:

- Poor quality raw materials leading to accidents.

- Inadequate or damaged personal protective equipment (PPE).

- Method (Process):

- Inefficient processes causing delays and stress.

- Lack of standardized safety procedures.

- Poor maintenance of the workplace environment.

- Measurement:

- Inadequate monitoring of safety practices.

- Lack of detailed incident reporting.

- Inconsistent safety audits.

- Mother Nature (Environment):

- Slippery floors due to rain or snow.

- Poor ventilation causing fatigue.

Step 3: Draw the Fishbone Diagram

Here’s how the diagram could look:

In the HSEQ example, High Workplace Injuries are the main issue; from the root cause perspective, the issues are as follows: from the (Man)-human perspective, it can be referred to as lack of training, from the (Machine) perspective, equipment failure, from the (Material) perspective, weakness or lack of appropriate personal protective equipment (Poor PPE), from the (Method) perspective, weakness in processes, from the (Measurement) perspective, inefficiency of audits, and from the (Mother Nature) perspective, adverse weather conditions can be referred to as the main causes.

Step 4: Analyze and Prioritize Causes

- From the diagram, you would now prioritize the categories with the most significant impact, like inadequate training or equipment failure. Focus corrective actions on these areas first.

Step 5: Implement Solutions

- Improve safety training programs.

- Conduct regular equipment maintenance.

- Standardize safety procedures.

- Improve workplace environment conditions.

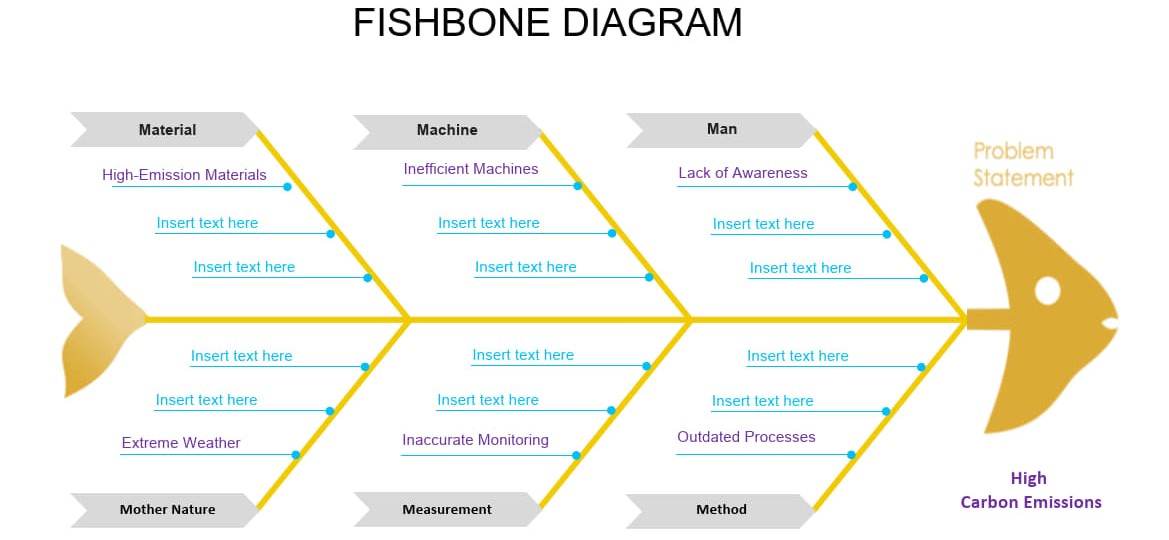

Example 2: ESG - High Carbon Emissions

Problem: High carbon emissions from manufacturing.

Step 1: Define the Problem

- Problem: High carbon emissions from production.

Step 2: Categorize Potential Causes Using 6M and 5W

6M Method:

- Man (People):

- Lack of awareness regarding sustainability practices.

- Failure to follow energy-saving protocols.

- Machine (Equipment):

- Energy-inefficient machinery.

- Old production lines using fossil fuels.

- Material:

- Use of high-emission raw materials.

- Inefficient waste management processes.

- Method (Process):

- Outdated manufacturing processes that consume more energy.

- Lack of sustainable sourcing and waste reduction strategies.

- Measurement:

- Lack of detailed carbon emission monitoring systems.

- Inconsistent tracking of emissions from different facilities.

- Mother Nature (Environment):

- Natural resource depletion causing supply chain disruptions.

- Extreme weather events disrupt energy sources.

5W Method:

- What: High carbon emissions.

- Why: Inefficient energy usage, outdated machinery, lack of sustainable practices.

- Where: Main manufacturing plant and distribution centers.

- When: Emissions increased during peak production months.

- Who: Manufacturing teams, management, supply chain managers.

Step 3: Draw the Fishbone Diagram

Here’s how the diagram could look:

In the ESG example, High Carbon Emissions are the main issue; from the root cause perspective, the issues are as follows: from the (Man) perspective, it can be referred to as Lack of Awareness, from the (Machine) perspective, inefficient tools and machinery, from the (Material) perspective, the use of materials with high emission potential, from the (Method) perspective, outdated processes, from the (Measurement) perspective, inaccurate monitoring, and from the (Mother Nature) perspective, extreme weather conditions can be referred to as the main root causes.

Step 4: Analyze and Prioritize Causes

- Prioritize fixing machinery inefficiencies and adopting renewable energy sources. Ensure data collection systems are set up to monitor emissions effectively.

Step 5: Implement Solutions

- Upgrade equipment to more energy-efficient models.

- Implement a carbon offset program.

- Introduce regular emission audits and improve sustainability training for employees.

Conclusion

The Fishbone Diagram, paired with the 6M and 5W methods, is an effective tool to systematically analyze the causes of problems in HSEQ and ESG contexts. By breaking down problems into manageable categories and asking the right questions, teams can more easily identify root causes and implement solutions to improve safety, quality, and sustainability practices.